Phone: CO 719-900-7791 • WA 253-447-7084 • Email: Service@integrityforms.com

What is Screen Printing?

Whatever your Apparel Need - Create an Impression with Custom Screen Printed Logowear

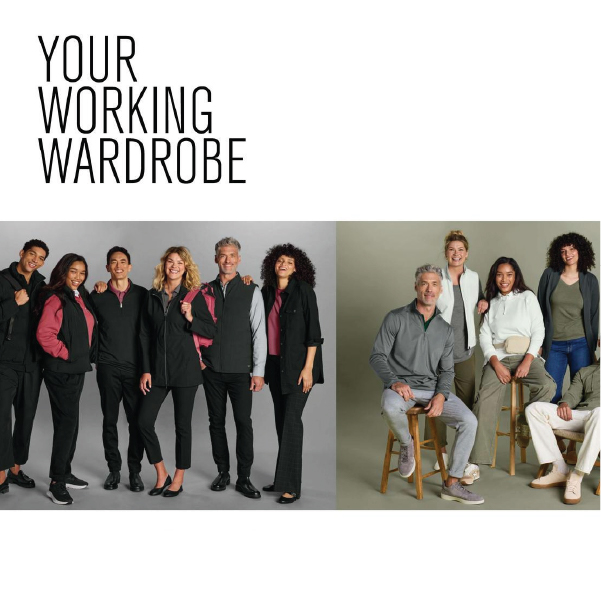

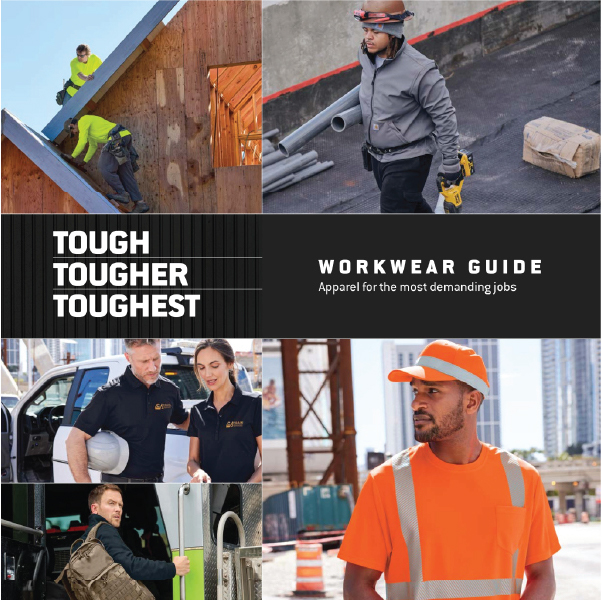

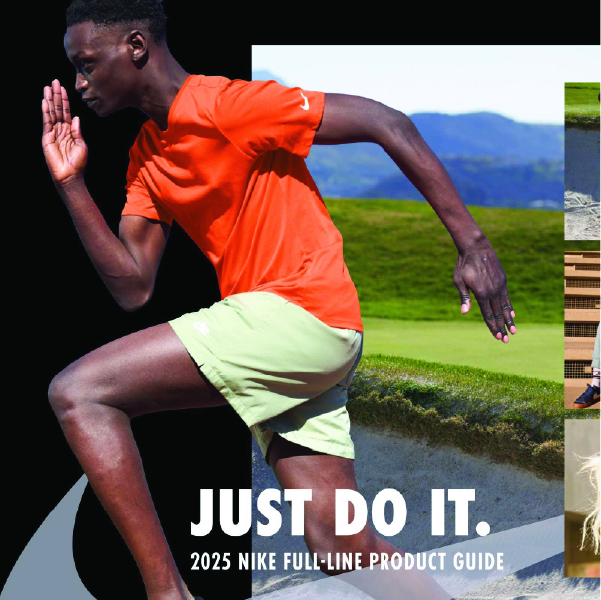

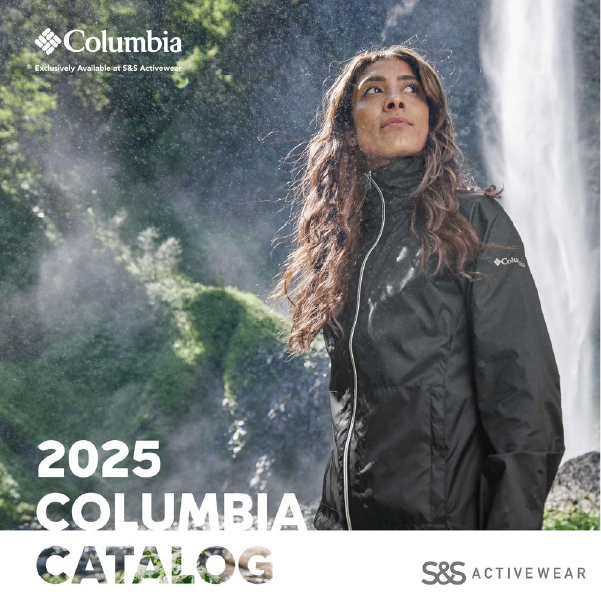

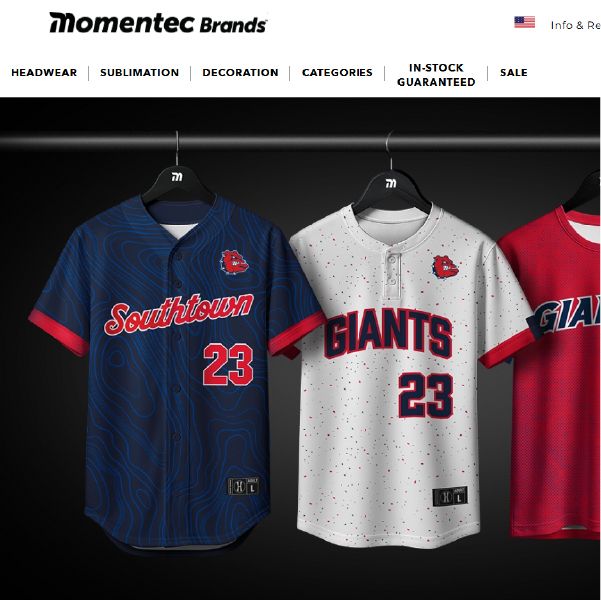

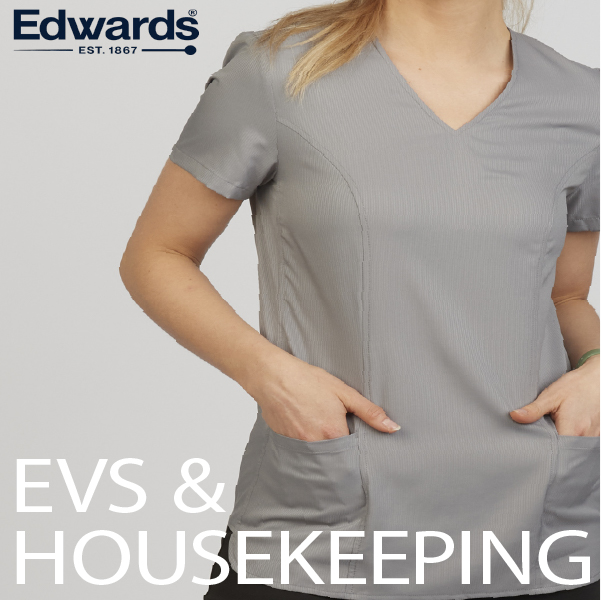

Start the process with the perfect apparel item. Click on the images below to view catalogs or let us know what you’re looking for and we’ll bring you options to choose from. Let us know the item #’s, sizes & quantities per size. You can upload your logo or artwork using the “Request Quote” button below and we will contact you to confirm your request. Contact us using the form, email, or call us direct ~ “the old fashion way” for any help needed. We’re good with whatever works best for you!

20 Catalogs to choose from below.. If you don't see it here, just ask!

Screen Printing Ordering Guideline

- Request your quote: Let us know what apparel item /style# you’re wanting. Search through our catalogs or let us know what you want i.e. Polos, Tee Shirts, Uniforms, Jackets etc. and we can also bring ideas to you.

- Place your order: Let us know you’re ready to begin. We will go over with you Quantities, Sizes, Colors, Turnaround time needed, delivery location(s) + any other specifics.

- Create a design: Design your screen printing project, including any text, graphics, and desired placement. We can work with your graphic designer, re-create your image or help you come up with the graphic design.

- Upload your design: Upload your design to our website or our FTP site.

- Review and approve: We will review your design for quality and approval & provide print ready proofs for your approval prior to production.

- Receive your order: Once approved, we will print and ship your order to the location(s) you relay to us. Once your item ships we will email tracking so you know when to expect your product.

What is Screen Printing?

Spot Color Screen Printing

Summary Definition: Spot color screen printing refers to using discrete colors, one by one, to print an image wherein each color is printed via a separate screen.

Halftone Printing

Brief Definition: Halftone printing creates shading and gradient effects through small dots for greater design detail and a subtler color transition.

Grayscale Printing

Definition Brief: Grayscale screen printing utilizes a gradient of different shades of black to generate the impression of depth and dimension, but without applying color.

Duotone Printing

Short Definition: Duotone printing uses two colors to produce a more vibrant and dynamic look compared to standard black-and-white printing, which often uses shades of the same color.

CMYK (4-Color) Printing

Definition Summary: CMYK printing applies four colors, cyan, magenta, yellow, and black, to build up a full spectrum of colors by overlapping ink layers.

Simulated Process Printing

Brief Definition: Simulated process printing uses a sequence of halftone dots and spot colors to mimic the appearance of full-color designs, especially on dark fabrics.

Conclusion

Screen printing is a powerful method for producing high- quality, durable prints across various applications. Whether for fashion, art, or promotional materials, the flexibility of screen printing techniques allows for endless creative possibilities. By understanding the different methods and their best uses, you can choose the right approach for your next project.

Definition and Process

- Creating the Stencil: A stencil is made on the mesh screen, which blocks certain areas from receiving ink. This can be done using various methods, including applying a light-sensitive emulsion that hardens when exposed to light.

- Setting Up the Screen: The screen is stretched tightly over a frame, ensuring that it is under tension for accurate printing.

- Applying Ink: Ink is placed on the screen, and a squeegee is used to push the ink through the open areas of the stencil onto the substrate below.

Curing the Ink: After printing, the ink must be cured (dried) to ensure it adheres properly to the material, which can be done through air drying or heat application.

Advantages

- Vivid Colors: Screen printing produces bright and bold colors, even on dark materials.

- Durability: The prints are long-lasting and resistant to fading.

- Cost-Effectiveness: Ideal for large production runs, as the setup costs are spread over many items.

Versatility: Can be used on a wide range of materials, including fabric, wood, and glass.

Screen printing remains a popular choice for both artistic and commercial applications due to its unique ability to produce high-quality, durable prints efficiently.

Applications

Screen printing is widely used across various industries for creating:- Textiles: Custom T-shirts, bags, and other clothing items.

- Posters and Artwork: Producing vibrant graphics and art prints.

- Promotional Materials: Items like decals and banners.

Industrial Applications: Printing on metal, glass, and plastic for various products.

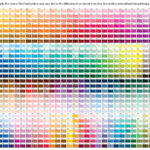

Ink Reference Charts

Click on thumbnails below for standard Plastisol colors – left & PMS Ink Colors on right.